Showroom

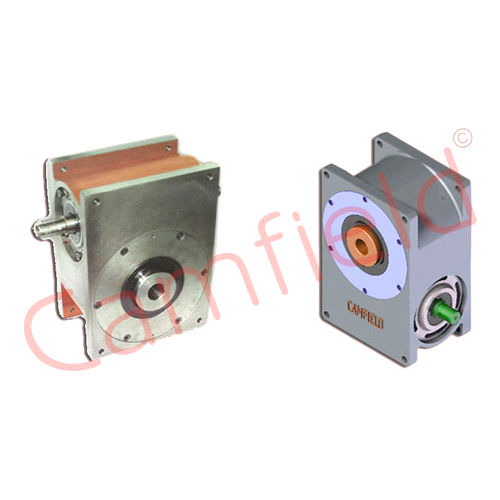

Cam indexing systems, crafted from stainless steel, are mechanical tools designed for precise positioning within industrial environments. Varying in size to meet diverse machinery requirements, they transform rotary motion into intermittent motion, facilitating accurate positioning on assembly lines and packaging equipment. These systems bolster manufacturing consistency, efficiency, productivity, and reliability.

The Packaging Machines Barrel Cam Indexer, by Camfield Engineers, is vital in industrial automation. Crafted from durable stainless steel, it ensures reliability in production. With indexing ranging from 6 to 8 and timing from 90 to 300 degrees, it synchronizes movements effectively. Essential for precise positioning, it boosts productivity in packaging machinery.

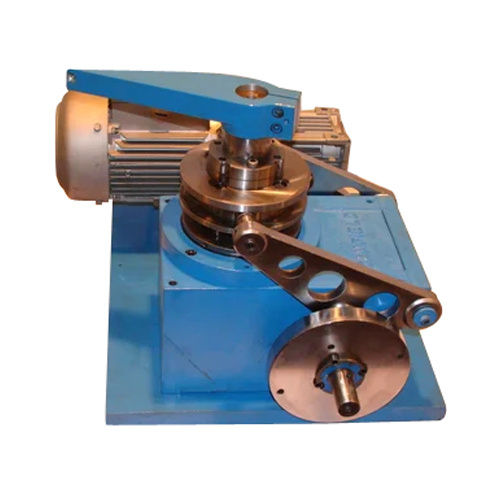

Pick and Place Automation Systems are sophisticated machinery for efficient material handling in manufacturing. They use Automated Groove Cams and Rotary Tables for tasks like riveting machine automation. Robotic arms with grippers pick and place components accurately. Designed for reliability and speed, they enhance productivity and ensure quality across industries.

Pharmaceutical Machine Automation integrates automated systems into manufacturing processes, employing Precision Automation Equipment for tasks like mixing and packaging. Advanced technology ensures accuracy and efficiency while meeting hygiene and regulatory standards. This automation reduces errors, ensures consistency, and enhances productivity in pharmaceutical production globally.

GST : 27AABCC4674Q1Z2

25, Shripal Service, Indl. Estate, Chincholi Pavan Baug, Off. S. V. Road, Malad (W), Mumbai - 400064, Maharashtra, India

Phone :08062845610

|

CAMFIELD ENGINEERS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |